Antideskilling: A whittler’s touchstone

January 23rd, 2013 By some bearsMakers have more opportunities than ever before to put together almost anything they can dream of from a kit of parts. They assemble these pre-fabricated parts and components from directions, and ultimately have a working product. But is it a craft?

This project works in the tradition of such kits, providing directions and parts for the maker to assemble. The goal is to whittle an egg from a piece of wood. Wiring electrical components creates the feedback mechanism that steers whittlers toward an outcome. But unlike kits ordered from Sparkfun, Maker:Shed and other DIY supply shops, assembling the electrical components does not itself constitute a finished product.The maker must exercise patience and manual skill manipulating wooden materials with a knife.

The hope here is that digital components mentor amateur crafters toward a tacit understanding of the raw materials they manipulate with tools. Whittling is a simple handicraft amenable to this sort of digital intervention. Newcomers to whittling usually undertake this simple project first: fashion an egg from a block of wood. The task reveals the responsiveness of wood to the force of a knife. The wood grain, the choice between a push or a pull stroke, and the wood’s hardness all have to be negotiated in this beginner’s project. The use of specialized tools is a contentious point among whittlers. Purists consider a sharp pocket knife the only suitable option since anything specialized reconstitute the practice as carving. They also reject the use of stainless steel knives, since they cannot be suitably sharpened.

Whittling is undertaken by individuals slowly passing time. As such it resists ever being subsumed by mechanization since this would remove whittling’s essential context. Master whittlers who find faces in fallen branches will never be “workers” in Rissati’s sense, since the spontaneous discovery of form with natural materials is never “simply labor produced by the non-creative hand.” Craftsmanship “depends on the judgement, dexterity and care which the maker exercises as he works.” This kit helps the amateur acquire a sensitivity to the relationship between material, tool and form, so that better judgement, dexterity and care can be applied to more ambitious projects in the future.

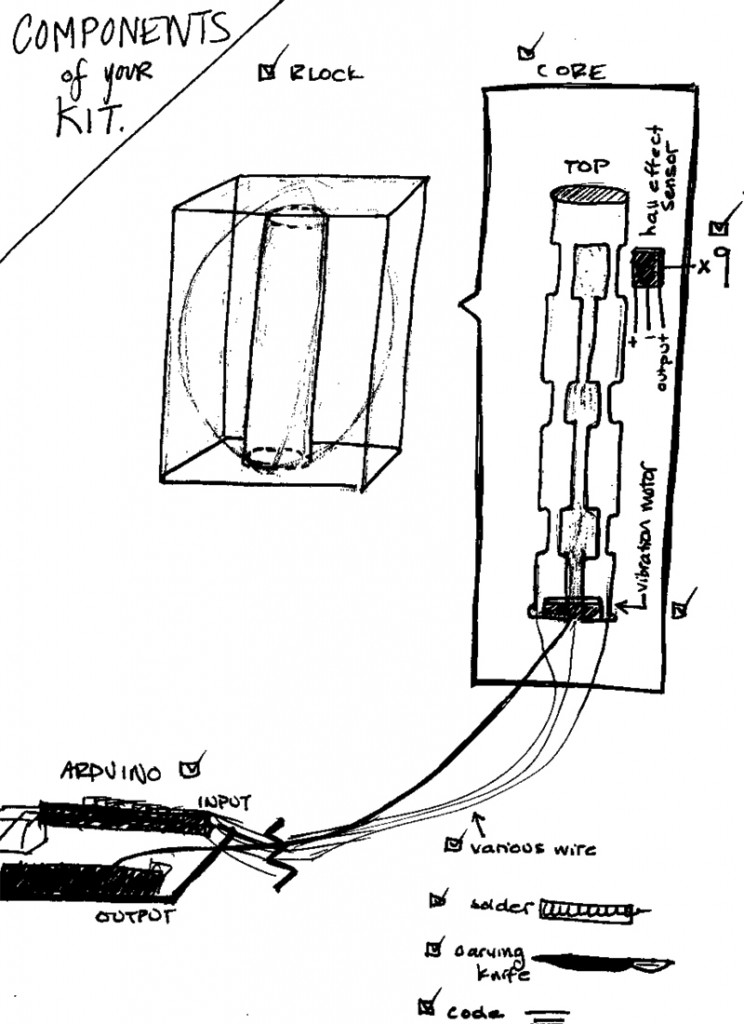

The Kit:

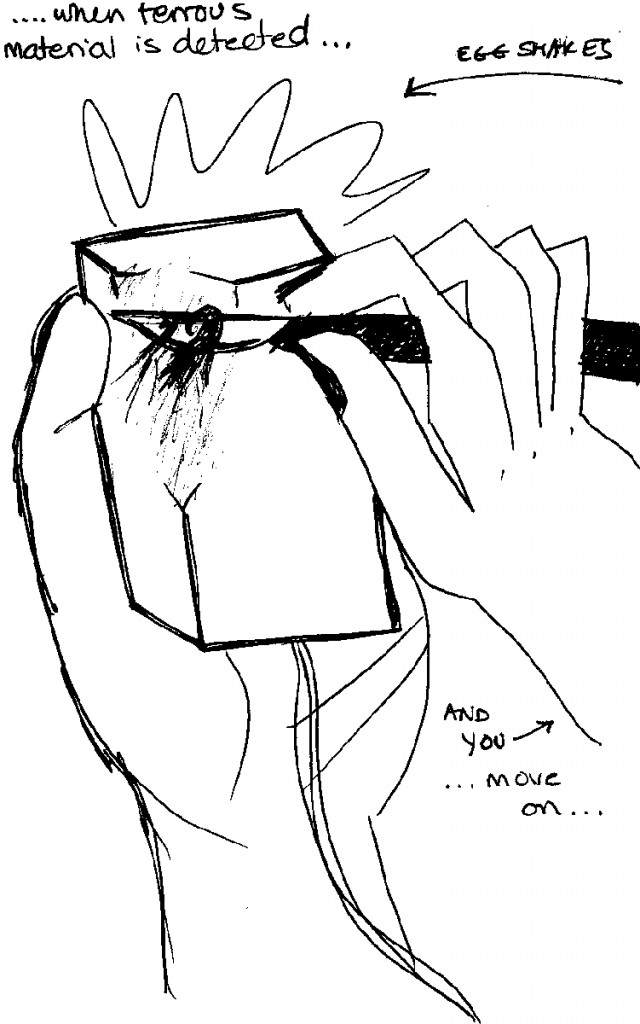

A block of balsa wood has a hollow core. Into this core we’ll insert a dowel with 3 notches on three facets, for a total of 9 notches. Into these notches, the maker will affix small and inexpensive hall effect sensors. These sensors act as proximity sensors for ferrous materials. When the steel (an iron alloy) knife comes within a calibrated distance to the sensor from outside the wood, the sensor will trigger a small vibration actuator that shakes the egg. This tells the whittler that the cut in this particular area is deep enough, and that it is time to move on to another area to shape the egg. Once the egg has been fashioned on all sides, the core can be removed. The end product contains no electronic parts. The wiring acts as tutor, and provides feedback to guide the amateur’s exploration.