Critical Review: Carvy – A Digital Stylus for Pottery Makers

Wednesday, December 9th, 2015

How I get there:

I started with a question, people use tools to shape the outside of the pottery piece. But how could the tools help people to craft the inside of clay.

Context and scenarios:

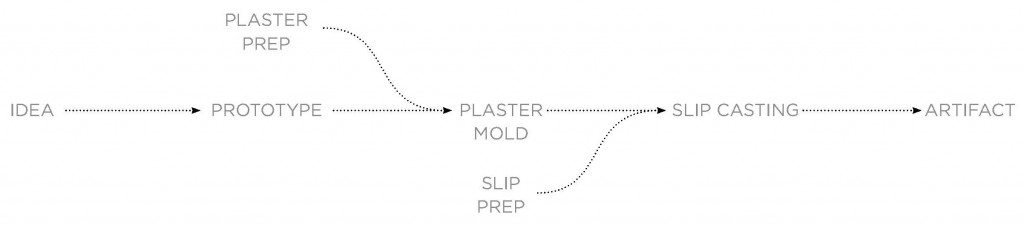

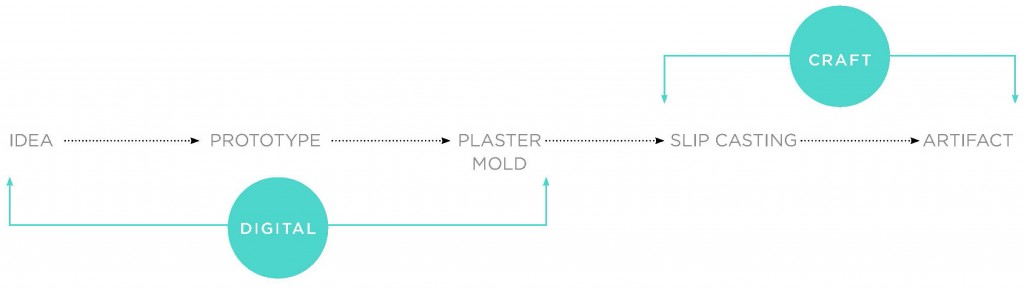

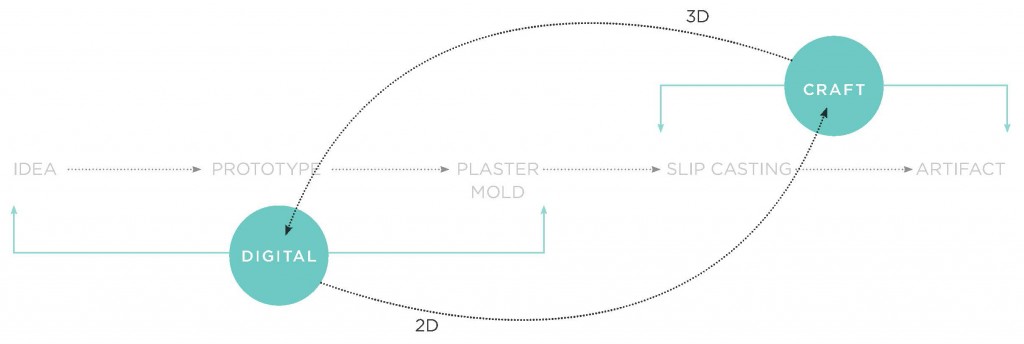

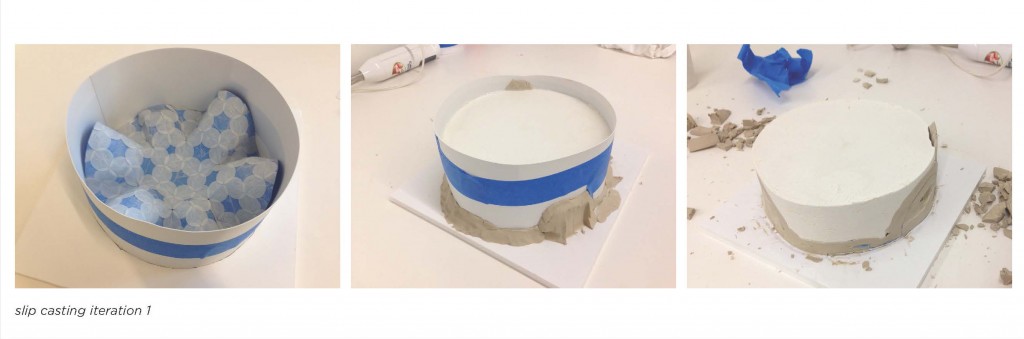

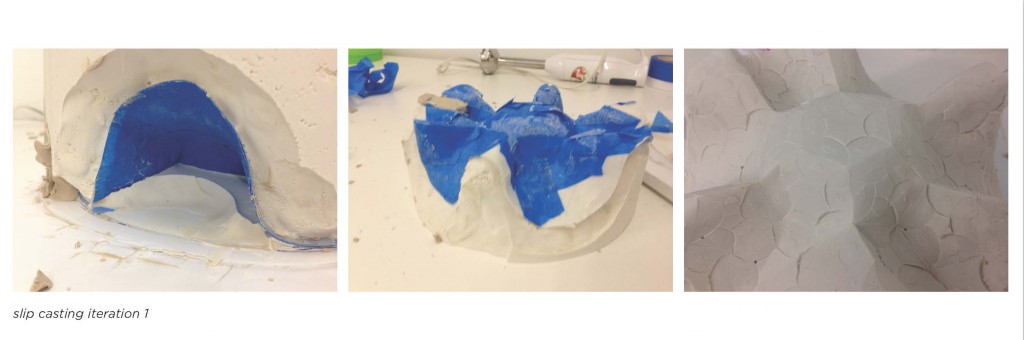

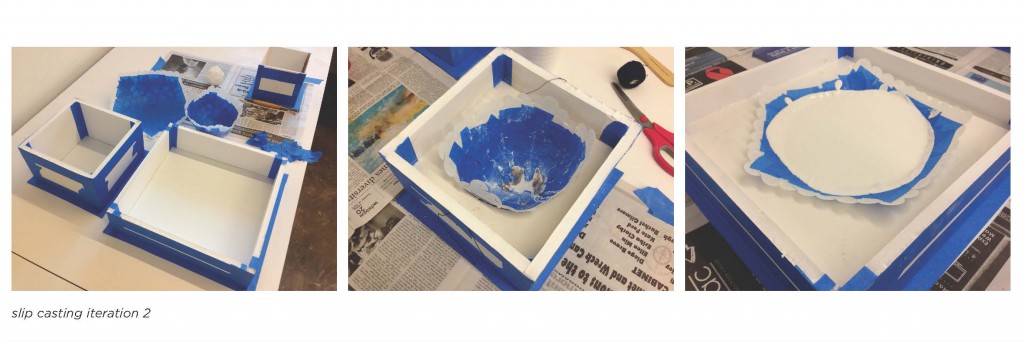

For the first scenario, maybe you are trying to hide something inside a ceramic jar. You need a tool to guide you to shape from inside. And one more use case will be that crafters need a tool to quantify the making process and the material. Under current technologies, they have to build a mould. Creating a mould is not easy or flexible at all. Thus a tool that could measure and estimate can be used to unify the shape of material even the crafters are not in the same place.

A state of smarter objects:

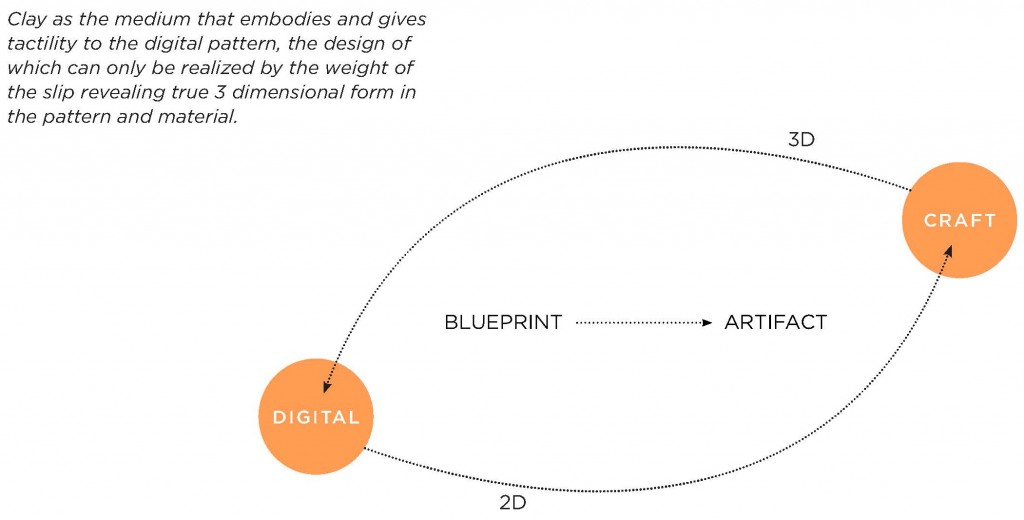

The state of smarter objects haven’t changed the material or the making process totally. Crafter can still use their workflow and material that they are familiar with. But at the same time, they can create a much digitalized relation with the material that they use. For example, a computational tool in ceramics might be a 3D-printer that mixed different soils. An traditional physical tool is the weight tool to measure the weights of soils used in mix a new material. A smart object will follow the mix procedure but also tell the crafter what’s the possible outcomes based on the current mix ratio.

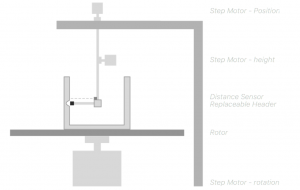

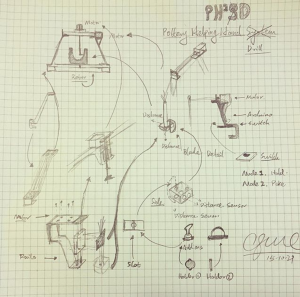

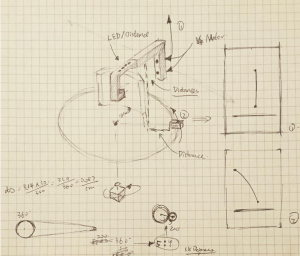

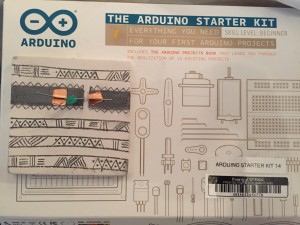

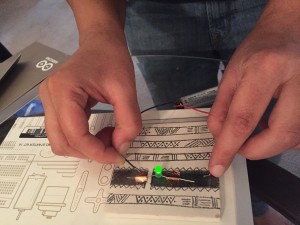

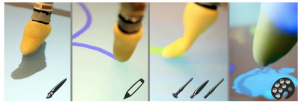

Then the question is, how could smarter objects help the transformative process of making. I would argue that in four directions. First, the smarter objects have limited computation but still, it’s computation. Computation could help shape the material in a much more strict way than human’s hand. Second, the smarter objects help people to learn without touching the material, in this case, the tool could mark a position without touching the clay. But using traditional tool, a physical marker will be left. Third, smarter tools brings extra functionality than the traditional tools. A digitalized brush could change its shape to provide vivid writing experiences. Forth, smarter tools pass digital data. With digital data, material’s shape can be imported to computer, to mobile phones. And the once the data flows to others, the data could be used creatively in generating new material practices. For example, masters can teach their students how to shape a pot remotely with this tool.

That opens possibilities:

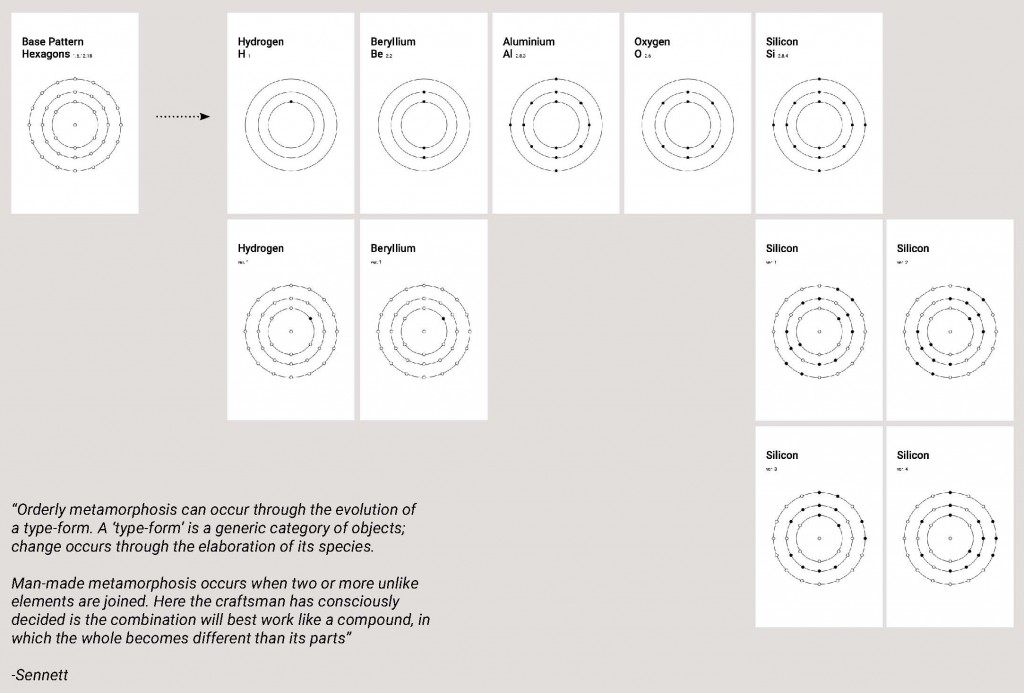

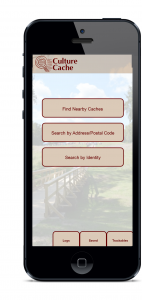

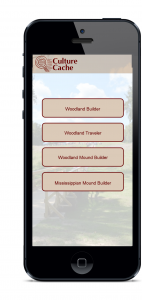

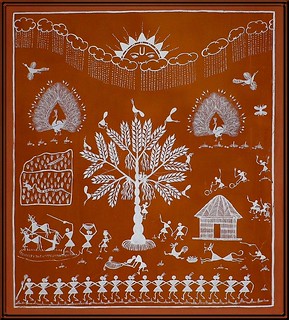

I can see the tool be utilized in many area, e.g. Logan’s project; Automatic drawing machine that draw a special pattern from computer; A way to teach and learn; A remoted connected handler; Transform data from the pottery maker or the WWW, the cultural side can be visualized…