Exploring type-form through orderly & man-made metamorphosis.

December 4th, 2015 By ievamDigital Intervention :

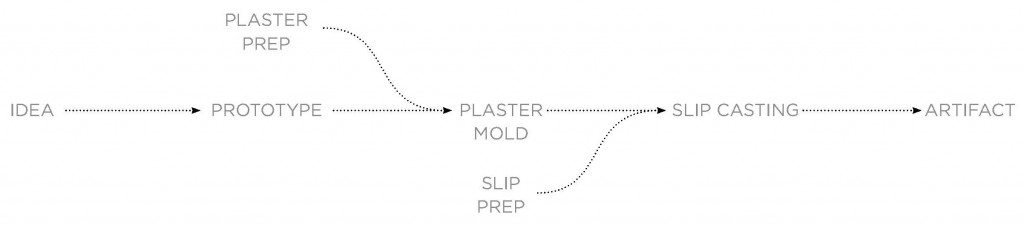

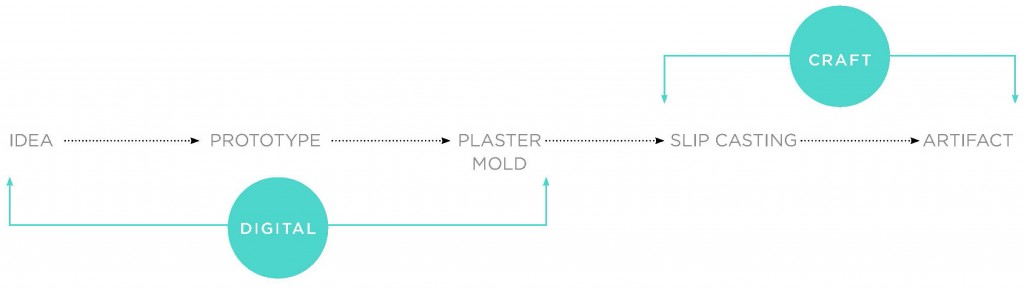

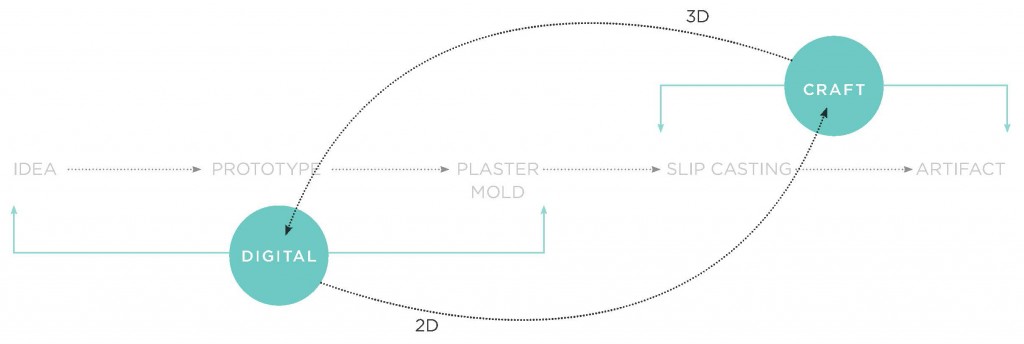

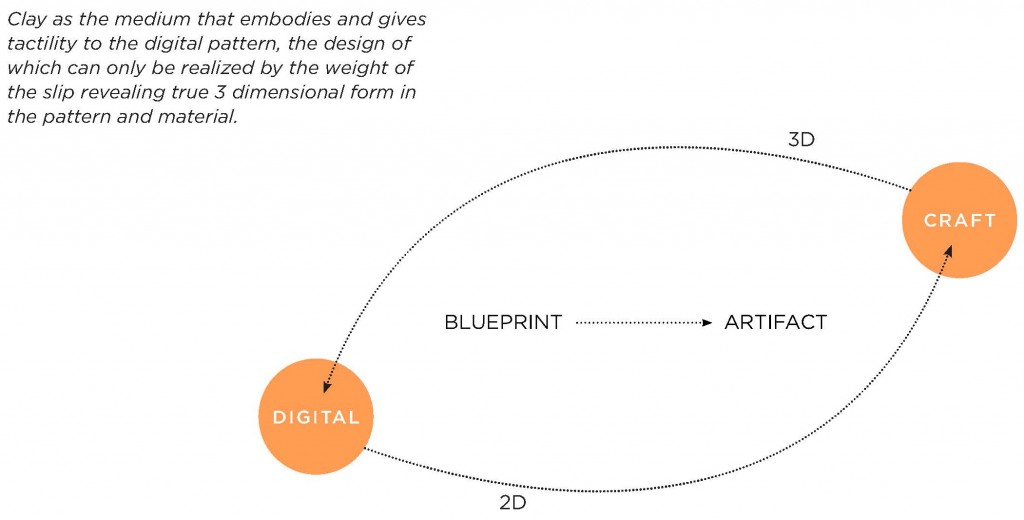

Initial concept featured a digital intervention in the process of developing a form and mold for ceramics slip casting.

Integrating an ongoing Industrial Design tessellations project, I sought out how to incorporate ceramic slip with the unconventional mylar material. The digital intervention would highlight the complexities of designing and building an unanticipated form and mold. As the tessellations are build from 2 dimensional pieces, the pattern design involves a transformation of 2 dimensional parts into a 3 dimensional form. Due to mylar’s flexible nature, the expectation was that the slip would reveal the true 3 dimensional form in the final form design.

Digital Prototype :

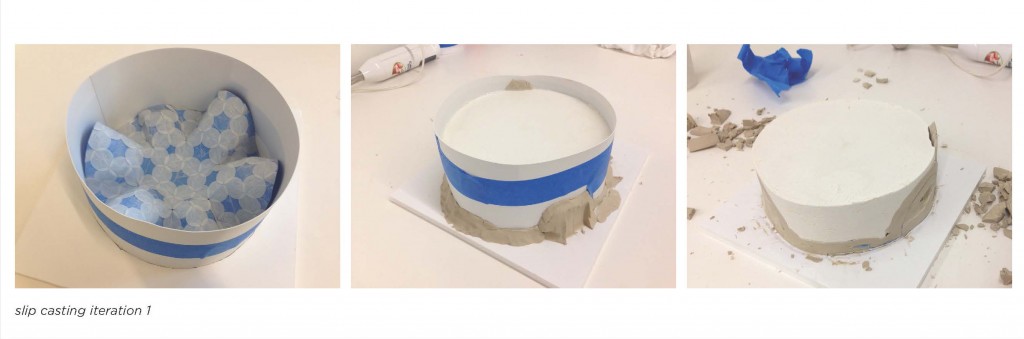

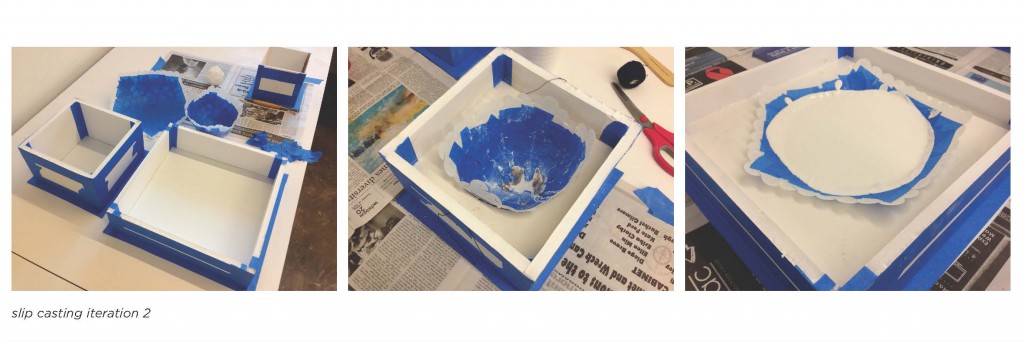

The development phase revealed several issues in the initial concept. Using processing to develop the pattern had its setbacks in the fact that pattern feasibility still needed to be tested by actually building the form. As well, the concept development behind the pattern influence was weak and stronger foundation was needed in the theory of what drives the pattern. The other issue was the use of mylar as a mold, weakening the casting of the slip into an artifact. The mold was too malleable, with the clay often distorting the actual form. The slip also cracked very easily in the process of casting.

The solution was to go back to slip casting in plaster, and focusing on developing a negative mold with the mylar forms.

Final Critical Design :

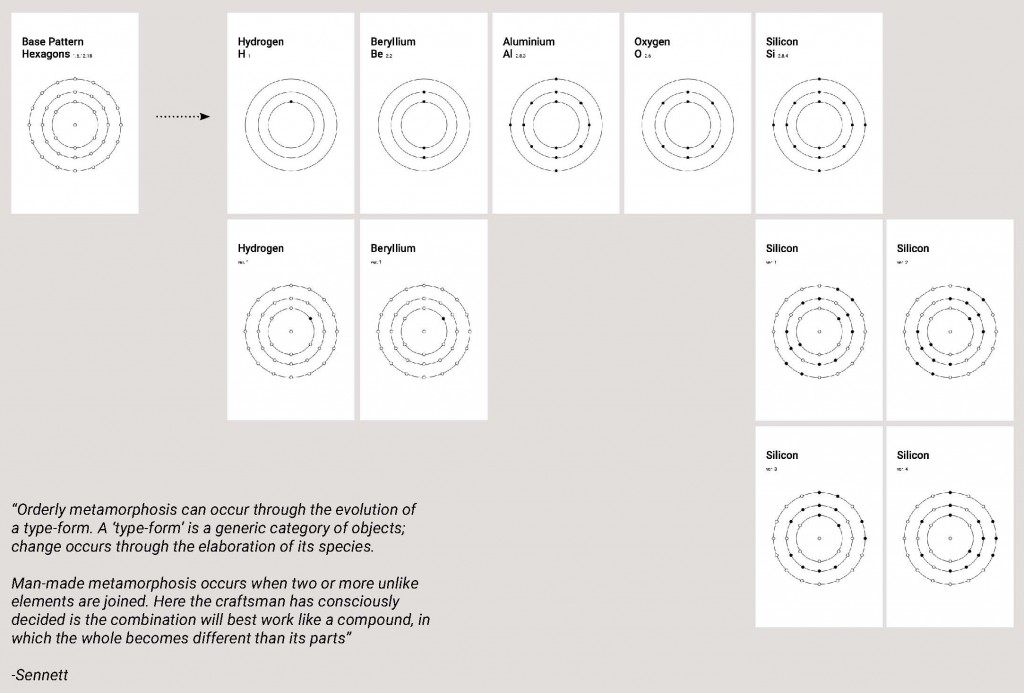

The final digital intervention featured using a base pattern of hexagons, arranged in 4 tiers. This produced a simple flat surface on which the tension points(pentagons) could be used to morph the flat form into a 3 dimensional surface. The inspiration for these tension points came from the chemical element makeup of Kaolin (Al2Si2O5(OH)4). Using the electron arrangements in the first 3 orbit shells, I would be able to specify where the tension points on the base pattern could be arranged.

This project development was highly inspired by Richard Sennett’s ideas on metamorphosis. This idea of seeing a design go through an “elaboration of its species” was mostly reflected working with the electron structure of Silicon. The pattern arrangement was highly modular and produced a variety of diverse forms.

The final design was realized through a process of building 4 plaster molds from 3 different pattern designs for Silicon, Beryllium, and Hydrogen. As this was my first time working with ceramics, a drop out mold was an ideal approach to test this project. My initial work with Silicon proved to be a great learning experience.

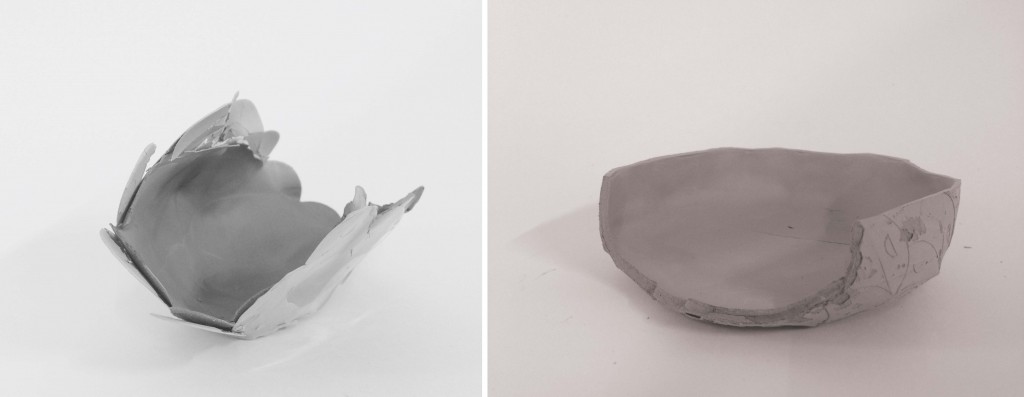

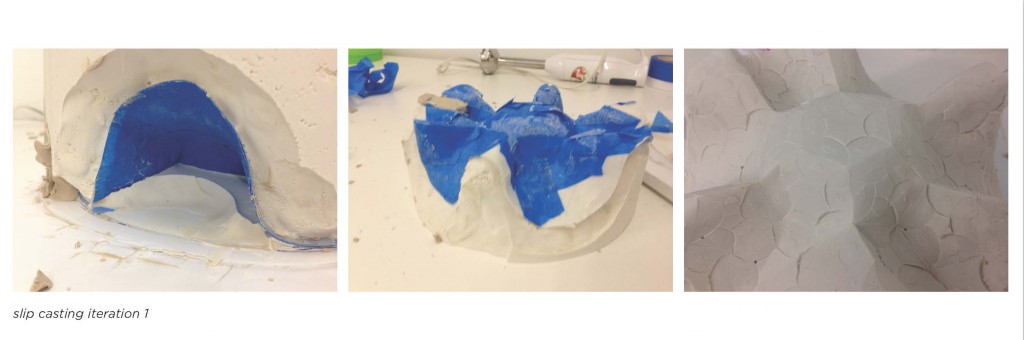

The biggest issued was the unanticipated interaction between mylar and casting plaster. While the form had no undercuts to start with, the positive mold turned out quite different. Due to the density and weight of the plaster, the mylar was deformed further than I anticipated, leaving several undercuts in the process. The final prototype was not usable for a basic drop out mold.

The next 2 sets of plaster molds we built a bit differently. I opted to drop the form into the plaster rather than pour over. But I found that this had its own issues, as plaster was still so dense that the weak mylar form buckles under the pressure. One solution was to pour plaster into the form at the same time, but this resulted in the form sinking too far to the bottom of the mold.

The final mold was submerged with layers of clay to provide structure during casting. Overall, the approach to this project required testing multiple proposals as working with such malleable and dense materials was enough of a contrast to cause several issues in the process. Additionally, the pattern design had its own limitations, as there was no way to anticipate how the from would reveal itself during the assembly process.

Tags: ceramics, slip casting, tessellations