Prototyping Process: Carvy – A Digital Stylus for Pottery Makers

December 9th, 2015 By Chong Guo

From Machine to Stylus

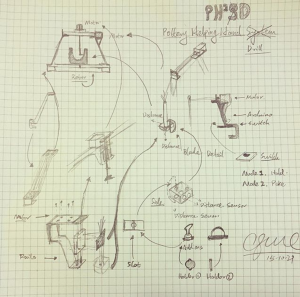

When I brought the idea of carving tool. The first thing came to my brain was Machines that make projects from MIT. The goal of those machines is to create more machines out of that. They made lots of things look like CNC machines. Then the question became, how did I make that. While I was drawing, a new idea was generated inspired by the 53 stylus pens for iPad.

The First Design

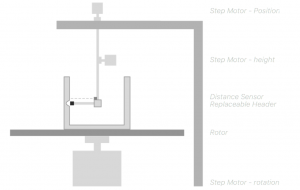

My first thought on the curving tool is a kind of 2D-Printer on the wheel. Two motors will move the pin in Y-Axis ( from top to bottom), and X-Axis (from the left to right, but always starts from the center of the wheel. The bottom of the extension bar has two sensors to detect the distances to the bottom and to the wall. Thus the machine could the vertically placed pin to the wall and start curving.

Prove of concept for the first prototype:

This prototype hasn’t been activated since it’s over complicated. It requires both customized materials and lots of trials.

Thoughts on the first prototype:

The first prototype actually starts with a hypnosis rather than a real world solution. So there are pros and cons for the first prototype. The down side definitely is the complexity of the system, it’s basically a 3D-printer without Z-axis movements. Another problem that will be generated by this design is the space issue. A low height structure will block user’s vision to the ceramic object. In addition to that, machines can only achieve single direction pock action, which is just a little part of the creative use of the carving tools.

However, the design has lots of benefits that couldn’t be compatible. Firstly, the design could run automatically. User could just draw simple lines in the software then the machine could be able to decode the drawing and transform it on the surface of the pottery piece. Secondly, the design could tell the thickness of the pottery piece’s bottom by moving the pin left and right. Since it has a distance sensor attached, and a fixed height. The differences of values can be considered as the thickness. Thirdly, the process of designing this machine informed me a lot of design principles, such as a changeable connection.

The Second Design

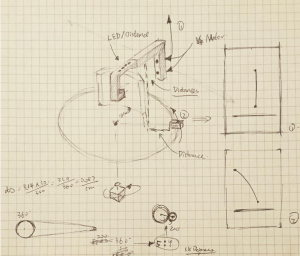

My second design simplified the machine. By changing it to a handheld device. User could be able to use it in a much flexible situation.

Key Approach to the second prototype:

The second prototype uses a C-shape structure to drop the pin in the middle of the pottery. A small led matrix shows the distance got from the distance sensor. The up and down movement can be captured by the distance sensor on the bottom. Another distance sense is used to detect the distance to the wheel. In this prototype the speed control of the wheel is added. The goal is to have a way to project the pin’s positions on the all 360 degrees.

Thoughts on second prototype:

The second prototype validates the way to combine distance sensor to grab the position of the tool’s pin. With data, we can also record a piece of user’s action and then use it as an instruction to help them repeat, or practice. But the device is still large and not easy to use.